Drilling

Drilling

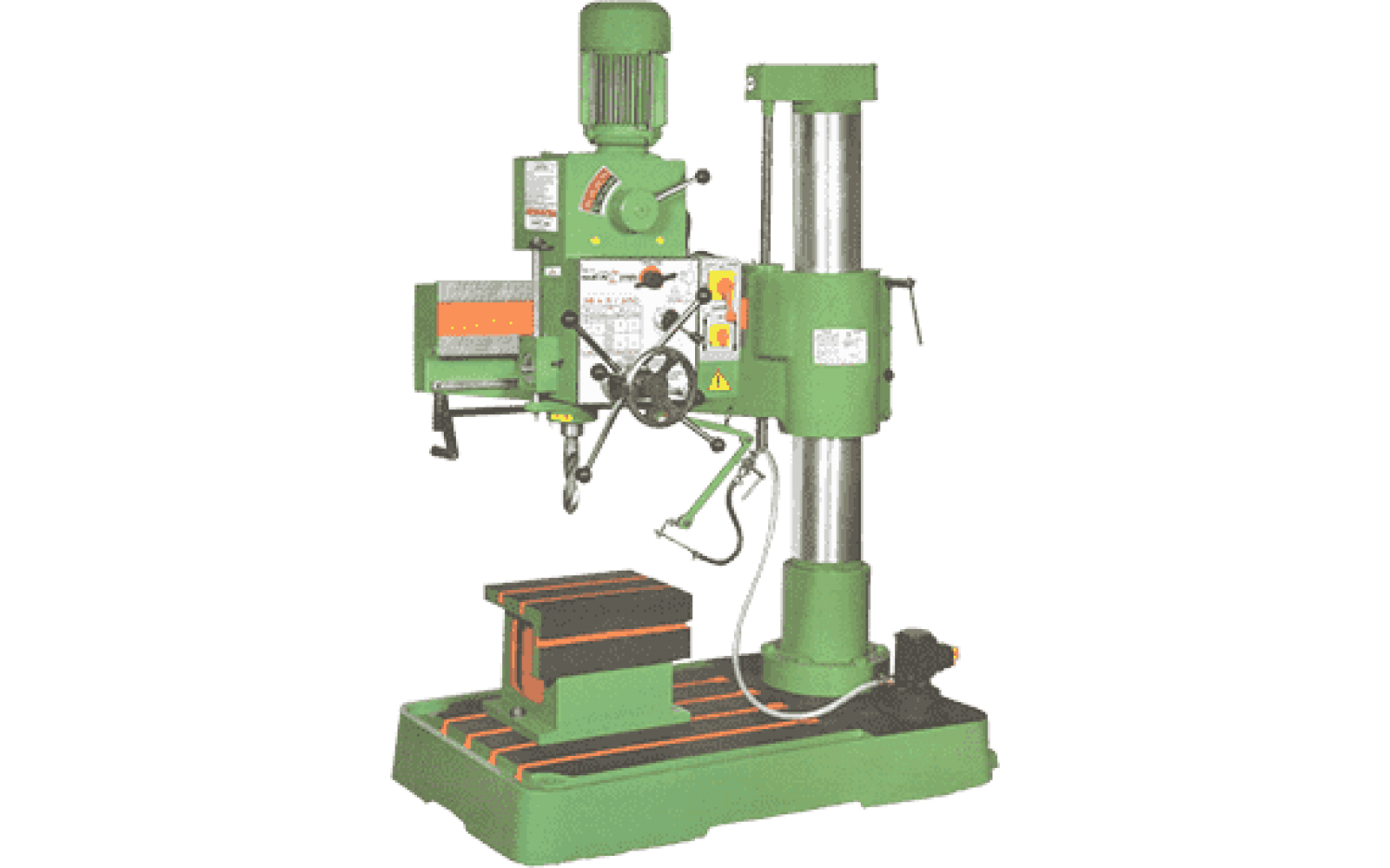

MAAN - 38mm All Geared Radial Drilling

Key Features

Main Spindle is made of "EN8" material and hardness

MT-bore internally grinded

Accuracy and run out of 0.01 to 0.03 in main spindle shaft

Pinion Shaft is made of "EN8" material and hardness

Provided 4-8 speeds by accurate balancing

Spindle sleeve-grinded

Work light[As per requirement]

Full size work table with accurate right-angled.[390X300][Surface Grinding is available as per your required]

Tapper Roller facility for better sliding of drill head an arm guide

Coolant system [As per requirement]

Speeds can easily change

Nitride Hardened "Ram"

All gears are made of alloy steel[Gear Material] and Heat treatment [50 to 60 HRC] hardened & Lapped running in oil bath fitted with splined shafts

Ram is accurately grinded and Honing process is done in the bore body containing "Ram"

All the gears assemble in the machine are perfectly sized according to requirement All Bearing [SKF/NSK[Japan]/NBC Bearing]

All Electrical parts are good quality.[Company:L&T]

Pinion and worm is grinded as per the sizes required

Column Design is heavy thickness and grinded as per the sizes required [column size:180mm]

Spindle reverse and tapping control[As per your required]

Specially spring type balanced spindle travel

Manual And Auto feed options

The Auto feed machanism is designed in such a manner that if incase the machine gets overloaded or the drill bit may get locked during operation the machine will automatically start slipping that will prevent any accident or any kind of damages

Drilling last capacity : 40mm

Heavy Duty structures

Strongly ribbed and thick walled base plate having built-in coolant tank. Generously Proportional & Well adequately ribbed base plates and column & arm for maximum rigidity and minimum deflection

This machine may be capable of drilling & milling & tapping & honing & counter-boring & spot facing & Reaming & boring and other similar utilities. Arm guide surface are precision scraping process

Wooden case available on demands

Note: All the above designs, dimensions and details are approximate only and we reserve the right to alter them without prior notice as we are improving the design.

- Accessories

- Technical Specification

Standard Accessories:

| Electrical consisting of two motors |

| Contractors & Limit Switch |

| R/F Switch |

| Wiring Etc. |

Optional Accessories: (At Extra Price)

| Box Table |

| Coolant Pump with Fitting |

| Machine Lamp |

| Extra Column Height |

| Drill Chuck with key & arbor |

| Drill Sleeve |

| Drill Vice |

| Special T-Bolts |

| Foundation Bolt |

| Service Tool |

| Wooden Box Packing & Forwarding |

| Sr No. | Model No. | MAAN 38X8/950 |

|---|---|---|

| A | Capacity | 38 mm. |

| B | Drilling Capacity | |

| In Mild Steel Having 300mpa Tensile Strength | 38mm. | |

| In Cast Iron Having 180bhn | 45mm. | |

| C | Tapping Capacity | 30mm |

| D | Boring | 75mm |

| E | Drilling in Head | |

| Taper in Spindle – (morse Tapper) | MT – 4 | |

| Spindle Travels – Auto/manaual | 200mm. | |

| No. of Spindle Speeds/Range | 8/50 – 1750 RPM | |

| No. of Auto Feeds | 2/0.06 – 0.15 | |

| F | Electrical | |

| Power Supply | 415v,3ph,50hz | |

| Drilling Head Motor | 2hp | |

| Arm Elevating Motor | 0.5hp | |

| G | Working Range | |

| Drilling Radius Min/Max. | 540 / 1050mm. | |

| Distance Between Base Plates To Spindle Min/Max. | 310/1050 mm. | |

| Drilling Head Traverse Max(Manual) | 500mm | |

| Vertical Traverse Of Arm [auto] | 715mm | |

| Column Sleeve Diameter 180mm | 180mm | |

| Rotation of Arm (Both Side) | 0-180DEG. | |

| H | Base Plate | |

| Working surface (L x W) | 850×650 | |

| No. of T-Slots & Nominal Size | 4/21 | |

| Weight Of Machine with electricals & standard accessories[approx] Net / Cross | 950 / 1150Kg | |

| I | Box Table Size[L X W X H] mm | 400 X 300 X 300 |

| J | Wooden Packing Dimension [L X W X H] | 1400X 1000X 1750 |